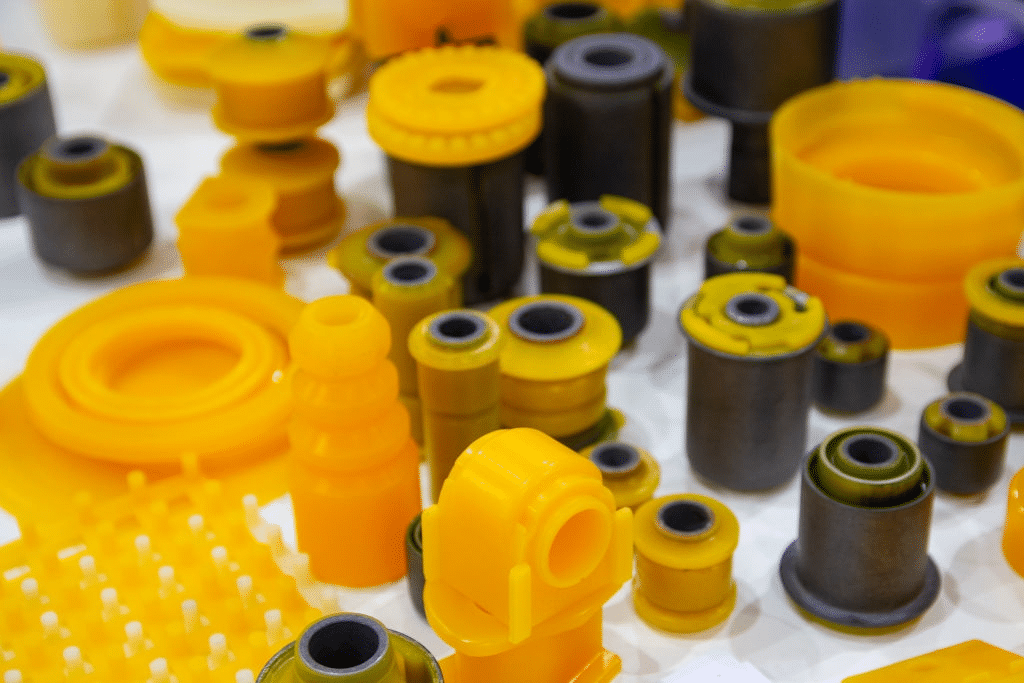

Flexible bushings are mechanical components that interface two moving metallic parts in a joint. They are cylindrical, and transfer relative motion between the two connected parts, by straining, rather than by shear or friction at the interface.

Flexible bushings were first used at engine mounting points in a Ford Plymouth car in the 1930s. Today, they are standard components in all automotive vehicles. Other than engine mount locations they are used in control arms, sway arms, and several other locations in the car.

The need for vibration isolation and shock absorption transcends the automotive industry. Flexible bushings are widely used in aviation jet engines where the stator components have to be isolated from the vibrating rotor.

In the construction industry, flexible bushings perform the role of isolating machine vibration from the foundation.

Flexible bushings are primarily made from two materials: Polyurethane (PU) and Synthetic Rubber.

As per a recent market survey of flexible bushings, the sale of Polyurethane bushings is showing an uptrend in the automotive aftermarket. In comparison, the growth of the rubber bushings sale is flat.

This could be an acknowledgment of the fact that PU bushings are extremely durable besides being strong and flexible. This is unlike Synthetic rubber bushings, which while performing well during their operating life, tend to wear out easily. They have poor tensile strength and low tear strength.

What is PU or Polyurethane

Polyurethane is an organic material, whose development was spurred by the requirement for high performing materials during World War II. It is artificially made by reacting Polyol (a form of alcohol) with a Diisocyanate or a polymeric isocyanate, using catalysts and additives.

The resulting material is then cured under elevated temperature and pressure, to form cross-linkages that lend PU its rugged and durable nature. By varying the amounts of additives and catalysts, Polyurethane properties such as density, shear modulus, and hardness can be tailored to suit every requirement. Thus a wide spectrum of materials can be created to meet specific industry applications.

What is Synthetic rubber

Synthetic rubber is also an organic material dating back to the nineteenth century. During World War I, the development got accelerated, due to the shortage of natural rubber. It is made by reacting monomers such as styrene and isoprene in the presence of additives. The resulting product is then vulcanized using sulfur to make it more durable.

Synthetic rubbers also have several variants. The most common Synthetic rubber, Styrene-Butadiene (SBR), is made by reacting the monomers styrene and butadiene.

From an engineering perspective both Polyurethane and Synthetic rubber are classified as elastomers. They can undergo large strains without fracture.

Elastomers are also ‘viscoelastic’. Their elastic property is a function of the strain rate. They have weak intermolecular forces and a low modulus of elasticity. Together, these properties make elastomers suitable for vibration isolation and shock absorption.

New cars, almost always, are factory fitted with rubber bushings. The first reason is that rubber is more flexible than PU and thus provides better NVH (Noise, Vibration, and Harshness) performance. The other reason, of course, is that rubber is cheaper. Given the number of flexible bushings within a car, you would want to bring down the unit cost of the vehicle.

The rubber flexible bushings on your car perform very well while they are new. However, within a few years, the vehicle will experience sudden shocks as it goes over a hump or encounters a pothole. You will begin to perceive vibration in the passenger cabin.

These are warning signs you must heed! It is now time to consider changing the bushings. If you defer this decision for too long, you are very likely to damage some critical parts or components in the car. A worn control arm bushing will lead to joint misalignments that can cause your tire to wear out prematurely. There could be other problems that can lead to accidents if the failure happens when the vehicle is in motion.

What type of bushing should you opt for as a replacement?

Do you again opt for new rubber bushings? Or would it be better to try out PU bushings? You have to decide by weighing several pros and cons.

What are the pros? Well PU bushings are available cheaper. But wait a minute…did we not say rubber bushings are cheaper than PU bushings?

Yes but that was for the OEMs who do bulk sourcing for factory fitting new vehicles. For the retail consumer, PU bushings are cheaper.

PU bushings have a longer life. On a shore scale of hardness, PU is almost three times as hard as rubber. Thus PU bushings are better able to withstand the harsh grind on the road. So, if you go for PU bushings, there is every chance that they will outlast your car.

PU bushings need only occasional maintenance. Is this a drawback? Not really. All you need to do is just remove the bushings, apply grease and reassemble. This can be done at home by watching some DIY (Do It Yourself) videos or going through car manuals. You end up saving time, money and vehicle downtime by avoiding a trip to the mechanic.

PU has a higher flexure modulus when compared with rubber. What does that mean in lay terms? Well, it means PU bushings are stiffer than rubber ones. The joint with PU bushing will flex or bend less when compared with the rubber bushing joint. How does this help? The relative motion of the suspension is considerably less.

You will have a better feel of the road when you are at the wheel. Vehicle cornering and other maneuvers become easier.

PU bushings can handle high temperatures and Ultra Violet (UV) radiation much better than rubber bushings. Besides high temperature, automotive components near the engine experience high thermal cycling. What is thermal cycling? It is the process of being subject to repeated cycles of high and low temperatures.

This is especially true in cold countries or in desert regions where the temperatures tend to fluctuate significantly. As you turn on the ignition and pick up speed, the temperature will climb from ambient to around 200 degrees F in a matter of minutes.

PU bushings have the resilience to handle these repeated thermal cycles, day after day, all round the year.

PU bushings are also impervious to the adverse chemical environment under the hood. There is no degradation in its life even after coming in contact with the greasy and oily matter within the joints of the vehicle.

Yes, PU bushings may squeak. This happens because its bond with the housing is mechanical. This bond may come off causing relative motion between the bushing and the sleeve. The consequent rubbing causes the squeak. To correct this, you have to regularly grease the joint and ensure that the bush fits snugly.

PU bushings, by being more rigid when compared to rubber bushings, exhibit lesser NVH performance. You will experience some vibration along with some jerkiness depending on the quality of the road.

How do rubber bushings stack up when compared with PU bushings

Rubber bushings show superior performance when it comes to shock absorption, vibration isolation, and noise reduction. Though they do not need maintenance, they wear out every few years and you will have to keep replacing them.

Before replacement, the worn-out rubber bushings need to be removed. This would be quite difficult to do at home. A hydraulic press may be needed to do the job. Alternatively, a flaming torch could also be used to burn out the rubber bushing.

All this will involve engaging the services of a vehicle mechanic. The consequence is downtime for the vehicle as well as additional expenses in the form of labor charges.

Rubber bushings perform poorly when it comes to resisting the atmospheric heat and ultraviolet radiation from the sun. They also deteriorate rapidly under thermal cycling. They degrade rapidly when exposed to rust, chemical oils, and lubricants in the vehicle.

Rubber bushings are made from Synthetic rubber, a copolymer made from petroleum derivatives. Hence in the retail aftermarket. not only are they pricier than PU bushings, the price even fluctuates with the price of oil!

The bond between the rubber bushing and the metal housing is a chemical one and hence there is no relative motion with the sleeve. Hence unlike PU bushings, rubber bushings never squeak.

So choosing between PU bushings and Rubber bushings involves a trade-off. It is very much driven by what, you, the customer is looking for.

The decision to shift to PU bushings will be driven by economic logic. PU bushings are rugged and will not wear out. It is likely they will outlast your vehicle. There is a bonus in terms of greater driving comfort.

Alternatively, if you choose to replace the worn-out rubber bushings with Synthetic rubber bushings, you will continue to enjoy a smooth ride with low vibration. This will also mean, you will be back where you are in a few years, keeping your date with the mechanic.